Ukraine, Zaporizhzhia,

Teplychna str., 16

ooo.technolitinvest@gmail.com

+38 (099) 2137834

+38 (067) 6116044

SERVICES

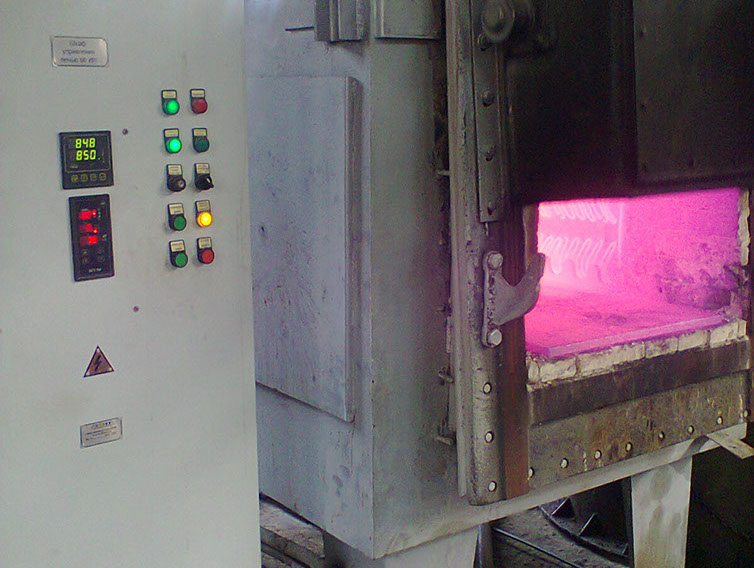

ТHERMAL PROCESSING

Thermal processing is a process in which the structure of steel lattice changes. Whereby the metal changes its physical properties at constant chemical properties.

LLC “Tehnolitinvest” performs such types of thermal processing as: Annealing – heating of the material in the furnace (furnace for thermal processing with the pull-out backstone) to a temperature of 900-950 ° C. Soak at this temperature is 3-4 hours, and then the material gets cool with the furnace.

Normalization – is the heating of the material in the furnace (furnace for thermal processing with the pull-out backstone) to a temperature of 900-950 ° C. Soak at this temperature is 3-4 hours, and then the material gets cool at the open air.

Annealing of welded metal constructions is the process of heating of the welded products up to a temperature of 600 degrees with the further cooling with the furnace (furnace for thermal processing with the pull-out backstone).

Hardening is a process in which the steel is heated above the critical temperature, and then quickly cools.

Sorbitizing is a special kind of steel processing thermally; it consists in heating the steel above the temperature of upper critical point and cooling at 100-600 ° C / min (using an air jet or in a liquid medium is heated to 300-500 ° C).